|

HOME

PRODUCTS

Coast Equipment & Services

Div. of O.A. Newton & Sons

PO Box 397

16356 Sussex Highway

Bridgeville, DE 19933

Sales: 302-337-3778

Fax: 302-337-3780

sales@coastequipment.com

Copyright © 2015 Coast Equipment & Services Co. All rights reserved.. |

Material Storage

Coast Equipment & Services Company Bolted, Welded and Corrugated Silos, In-plant Bins and Accessories:

Bolted

silos are constructed of sidewall panels approximately

5’ wide by 8’ wide. These staves are precision

cut, formed and factory-coated. They are versatile enough

that we can produce tanks in sizes up to 200’ in diameter

and 200’ high, subject to design restrictions.

Bolted

silos are constructed of sidewall panels approximately

5’ wide by 8’ wide. These staves are precision

cut, formed and factory-coated. They are versatile enough

that we can produce tanks in sizes up to 200’ in diameter

and 200’ high, subject to design restrictions.

Our

bolted silos are designed to meet the requirements of heavy

usage. Hopper-bottom silos utilize a structurally designed

hopper-to-sidewall connection that is reinforced at the

hopper springline. Truck and rail drive-through skirt openings

are reinforced with heavy wall square and rectangular tubing

to increase stability.

Welded Silos

Welded Silos |

Welded

silos are qualified to ASME Section IX. Shell seams

are full penetration welded using sub-arc welding processes

with copper backup. Other seams may e made with gas metal

arc welding, flux-colored arc welding or submerged arc welding,

as appropriate.

Standard

welded tank diameters range from 8’ to 14’ and

standard heights are 18’ to 72’. Welded silos

are typically shipped as single piece units, ready to install

upon arrival at the jobsite. However, when taller silos

are desired, sections can be shipped for welding onsite.

Skirted silos up to 12’ in diameter and 80’ long

can be shipped on self unloading trailers for domestic deliveries.

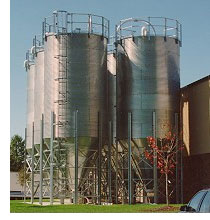

Corrugated Silos

Corrugated Silos |

Corrugated

silos are constructed of galvanized steel and range

in capacity from 5,000 to 245,000 lbs., 6 ft. to 21 ft.

in diameter. These silos require minimal maintenance and

are highly resistant to weather conditions and industrial

pollution. They help eliminate the possibility of costly

production downtime due to interruption in material deliveries,

because you're assured of a good reserve supply. Plant efficiency

is increased because materials move from the bulk bins automatically

to points of need with a minimum of operator involvement.

|

|

Bolted

Silo - Standard Accessories

Furnished

With Tank

- 2’

x 5’ walk-in door in skirt below hopper

- 20”

center roof dome with cover plate

- Foundation

anchor bolts and saddles

- Hardware

and gasketing for assembly of tank

Optional

Accessories

- 3’-0”

x 6’-8” walk-in door with a free air louver in

lieu of standard 2” x 5” door

- Hillside

flange in deck for mounting filter (size and weight required)

- Louvers

for ventilation in skirt below hopper

- 20”

diameter access in hopper or sidewall

- 12”

diameter aluminum slide gate with control handle

- Stub

and flanged nozzles in deck and sidewall

- Openings

for level indicators

- 20”

diameter ventilator in deck

- Plastic

cap bolts

- 20”

diameter dust-tight manhole in deck

- 20”

or 24” diameter combination manhole, pressure vacuum

valve, (2 oz. pressure and 0.5

oz. vacuum). Recommended for use with filter.

- 20”

diameter hillside dome with cover for deck

Bolted

Tank standard sizes – 1:12 bolted deck

|

Nominal

Size (in feet)

|

Capacity

- Level full (in cubic feet)

|

|

Diameter

|

Eave

Height

|

Flat

without bottom

|

Tanks

with 45° Hopper

|

Tanks

with 60° Hopper

|

|

9

|

24

|

1,610

|

1,275

|

1,145

|

|

32

|

2,150

|

1,810

|

1,680

|

|

40

|

2,690

|

2,350

|

2,215

|

|

48

|

3,230

|

2,890

|

2,745

|

|

56

|

3,765

|

3,425

|

3,280

|

|

64

|

4,305

|

3,965

|

3,815

|

|

72

|

4,840

|

4,505

|

4,350

|

|

80

|

5,380

|

5,040

|

4,885

|

|

88

|

5,915

|

5,580

|

5,420

|

|

96

|

6,450

|

6,115

|

5,995

|

|

12

|

24

|

2,875

|

2,145

|

1,830

|

|

32

|

3,825

|

3,105

|

2,780

|

|

40

|

4,785

|

4,060

|

3,735

|

|

48

|

5,745

|

5,020

|

4,690

|

|

56

|

6,700

|

5,975

|

5,650

|

|

64

|

7,660

|

6,935

|

6,610

|

|

72

|

8,620

|

7,890

|

7,565

|

|

80

|

9,575

|

8,855

|

8,525

|

|

88

|

10,540

|

9,815

|

9,485

|

|

96

|

11,505

|

10,775

|

10,440

|

|

15

|

24

|

4,485

|

3,160

|

2,640

|

|

32

|

5,980

|

4,655

|

4,130

|

|

40

|

7,475

|

6,150

|

5,625

|

|

48

|

8,970

|

7,645

|

7,125

|

|

56

|

10,465

|

9,140

|

8,620

|

|

64

|

11,960

|

10,634

|

10,110

|

|

72

|

13,465

|

12,140

|

11,605

|

|

80

|

14,965

|

13,640

|

13,100

|

|

88

|

16,470

|

15,145

|

14,590

|

|

96

|

17,970

|

16,645

|

16,085

|

|

18

|

24

|

6,455

|

4,275

|

3,300

|

|

32

|

8,605

|

6,425

|

5,450

|

|

40

|

10,760

|

8,580

|

7,605

|

|

48

|

12,910

|

10,730

|

9,755

|

|

56

|

15,065

|

12,880

|

11,910

|

|

64

|

17,225

|

15,045

|

14,050

|

|

72

|

19,390

|

17,210

|

16,195

|

|

80

|

21,555

|

19,370

|

18,340

|

|

88

|

23,715

|

21,535

|

20,485

|

|

96

|

25,880

|

23,695

|

22,630

|

|

21

|

24

|

8,790

|

5,445

|

3,795

|

|

32

|

11,725

|

8,375

|

6,715

|

|

40

|

14,675

|

11,325

|

9,630

|

|

48

|

17,585

|

14,235

|

12,545

|

|

56

|

20,535

|

17,185

|

15,460

|

|

64

|

23,475

|

20,130

|

18,375

|

|

72

|

26,420

|

23,080

|

21,295

|

|

80

|

29,370

|

26,020

|

24,210

|

|

88

|

32,315

|

28,970

|

27,125

|

|

96

|

35,260

|

31,915

|

30,040

|

|

26

|

32

|

17,285

|

11,525

|

8,315

|

|

40

|

21,605

|

15,845

|

12,635

|

|

48

|

25,930

|

20,165

|

16,950

|

|

56

|

30,270

|

24,510

|

21,270

|

|

64

|

34,615

|

28,855

|

25,590

|

|

72

|

38,960

|

33,195

|

29,905

|

|

80

|

43,300

|

37,540

|

34,225

|

|

88

|

47,645

|

41,885

|

38,545

|

|

96

|

51,990

|

46,225

|

42,860

|

|

29

|

32

|

23,315

|

14,465

|

9,670

|

|

40

|

27,890

|

20,055

|

15,260

|

|

48

|

33,495

|

25,640

|

20,845

|

|

56

|

39,110

|

31,230

|

26,435

|

|

64

|

44,715

|

36,815

|

32,020

|

|

72

|

50,320

|

42,400

|

37,610

|

|

80

|

55,930

|

47,990

|

43,195

|

|

88

|

61,535

|

53,575

|

48,785

|

|

96

|

67,140

|

59,165

|

54,370

|

|

32

|

32

|

26,940

|

16,645

|

10,265

|

|

40

|

33,725

|

23,410

|

17,025

|

|

48

|

40,510

|

30,170

|

23,785

|

|

56

|

47,285

|

36,930

|

30,545

|

|

64

|

54,070

|

43,690

|

37,310

|

|

72

|

60,845

|

50,450

|

44,070

|

|

80

|

67,625

|

57,210

|

50,830

|

|

88

|

74,410

|

63,970

|

57,590

|

|

96

|

81,185

|

70,730

|

64,350

|

|

38

|

32

|

37,710

|

20,930

|

10,320

|

|

40

|

47,185

|

30,375

|

19,760

|

|

48

|

56,660

|

39,815

|

29,205

|

|

56

|

66,140

|

49,260

|

38,645

|

|

64

|

75,615

|

58,700

|

48,090

|

|

72

|

85,090

|

68,145

|

57,530

|

|

80

|

94,570

|

77,585

|

66,975

|

|

88

|

104,045

|

87,030

|

76,415

|

|

96

|

113,525

|

96,470

|

85,860

|

|

55

|

40

|

95,650

|

|

|

|

48

|

114,840

|

|

|

|

56

|

134,030

|

|

|

|

64

|

153,220

|

|

|

|

72

|

172,415

|

|

|

|

80

|

191,605

|

|

|

|

88

|

210,795

|

|

|

|

96

|

229,985

|

|

|

Welded

Silo - Standard Accessories

Furnished

With Tank

- 3’8”

x 6’8” walk-in door with a free air louver (skirted

tank only)

- Foundation

anchor bolts and clips

Optional

Accessories

- Hillside

flange in deck for mounting filter (size and weight required)

- 20”

diameter access in hopper or sidewall

- 12”

diameter aluminum slide gate with control handle

- Stub

and flanged nozzles in deck and sidewall

- Openings

for level indicator

- 20”

diameter manhole/ventilator in deck

- 20”

or 24” diameter dust-tight manhole in deck

- 20”

or 24” diameter combination manhole, pressure vacuum

valve, (2 oz. pressure and 0.5 oz. vacuum). Recommended

for use with filter.

- 20”

diameter hillside dome with cover for deck

- Special

hopper outlet opening

- Deck

perimeter guardrails with toe board (OSHA), aluminum construction

(alternate—hot-dip galvanized)

- Outside

ladders with safety enclosures and rest platforms (OSHA),

hot-dip galvanized (alternate—aluminum construction)

- Crossovers

for use between tanks (OSHA), aluminum construction (alternate—hot-dip

galvanized)

- Special

hopper outlet openings

- Exterior

push caps for nut protection

- Deck

perimeter guardrails with toe board (OSHA)*

- Outside

ladders with safety enclosures and rest platforms (OSHA)*

- Crossovers

for use between tanks (2’–6”, 4’ 6’

x 8’ long) (OSHA)*

- Spiral

stairways (OSHA)*

- Conveyor

supports*

Welded

Tank standard sizes - 10° deck

|

Nominal

Size (in feet)

|

Capacity

- Level full (in cubic feet)

|

|

Diameter

|

Eave

Height

|

Tanks

with 45° Hopper

|

Tanks

with 60° Hopper

|

|

8

|

18

|

530

|

575

|

|

24

|

830

|

875

|

|

30

|

1,125

|

1,170

|

|

36

|

1,425

|

1,470

|

|

42

|

1,720

|

1,765

|

|

48

|

2,020

|

2,065

|

|

54

|

2,315

|

2,360

|

|

60

|

2,615

|

2,660

|

|

66

|

2,910

|

2,955

|

|

72

|

3,205

|

3,255

|

|

9

|

18

|

685

|

695

|

|

24

|

1,060

|

1,070

|

|

30

|

1,435

|

1,445

|

|

36

|

1,815

|

1,825

|

|

42

|

2,190

|

2,200

|

|

48

|

2,565

|

2,575

|

|

54

|

2,940

|

2,955

|

|

60

|

3,320

|

3,330

|

|

66

|

3,695

|

3,705

|

|

72

|

4,070

|

4,080

|

|

10

|

18

|

855

|

810

|

|

24

|

1,320

|

1,275

|

|

30

|

1,785

|

1,740

|

|

36

|

2,250

|

2,205

|

|

42

|

2,715

|

2,670

|

|

48

|

3,180

|

3,135

|

|

54

|

3,645

|

3,600

|

|

60

|

4,110

|

4,065

|

|

66

|

4,575

|

4,530

|

|

72

|

5,040

|

4,995

|

|

11

|

18

|

1,055

|

930

|

|

24

|

1,615

|

1,490

|

|

30

|

2,180

|

2,050

|

|

36

|

2,740

|

2,615

|

|

42

|

3,300

|

3,175

|

|

48

|

3,865

|

3,740

|

|

54

|

4,425

|

4,300

|

|

60

|

4,990

|

4,865

|

|

66

|

5,550

|

5,425

|

|

72

|

6,115

|

5,990

|

|

12

|

18

|

1,330

|

1,040

|

|

24

|

2,000

|

1,705

|

|

30

|

2,665

|

2,375

|

|

36

|

3,335

|

3,045

|

|

42

|

4,005

|

3,715

|

|

48

|

4,675

|

4,385

|

|

54

|

5,345

|

5,055

|

|

60

|

6,015

|

5,725

|

|

66

|

6,680

|

6,390

|

|

72

|

7,350

|

7,060

|

|

13

|

18

|

1,515

|

1,145

|

|

24

|

2,300

|

1,930

|

|

30

|

3,085

|

2,715

|

|

36

|

3,870

|

3,500

|

|

42

|

4,655

|

4,285

|

|

48

|

5,440

|

5,070

|

|

54

|

6,225

|

5,855

|

|

60

|

7,015

|

6,640

|

|

66

|

7,800

|

7,425

|

|

72

|

8,858

|

8,210

|

|

14

|

18

|

1,705

|

1,235

|

|

24

|

2,615

|

2,145

|

|

30

|

3,530

|

3,060

|

|

36

|

4,440

|

3,970

|

|

42

|

5,350

|

4,880

|

|

48

|

6,260

|

5,790

|

|

54

|

7,170

|

6,700

|

|

60

|

8,080

|

7,610

|

|

66

|

8,990

|

8,525

|

|

72

|

9,900

|

9,435

|

Corrugated

Silo – Standard Accessories

Furnished

with Tank:

- G-90

galvanized finish (interior and exterior)

- Depending

on silo size, provided with roof-top perimeter guard rail

toeboard

- 22"

diameter center opening and latching lid

- 16"

diameter discharge opening and collar

Optional

Accessories:

- Vacuum

take off boxes with probes

- Aluminum

slide gate with hand wheel

- View

window

- Crosswalk

- Truck

fill lines

- Level

indicators

Corrugated

Silo standard sizes – 10° roof

|

Diameter

(in feet)

|

Height

to center of roof lid

|

Usable

pounds (based on 35 lbs/cubic ft)

Tanks

with 45° Hopper Slope

|

Height

to center of roof lid

|

Usable

pounds (based on 35 lbs/cubic ft)

Tanks

with 60° Hopper Slope

|

|

9

|

13'

|

13,475

|

16'

|

16,100

|

|

15'

10"

|

19,390

|

18'

7"

|

22,050

|

|

18'

6"

|

25,305

|

21'

4"

|

28,000

|

|

21'

2"

|

31,220

|

24'

|

33,775

|

|

23'

10"

|

37,135

|

26'

7"

|

39,725

|

|

26'

5"

|

43,050

|

29'

4"

|

45,675

|

|

29'

|

48,965

|

31'

11"

|

51,625

|

|

31'

8"

|

54,880

|

34'

7"

|

57,575

|

|

34'

4"

|

60,795

|

37'

4"

|

63,525

|

|

37'

|

66,710

|

-

|

-

|

|

12

|

14'

11"

|

23,170

|

18'

10"

|

28,875

|

|

17'

7"

|

33,635

|

21'

6"

|

39,340

|

|

20'

4"

|

44,065

|

24'

1"

|

50,645

|

|

22'

11"

|

54,495

|

26'

10"

|

60,200

|

|

25'

7"

|

64,960

|

29'

6"

|

70,665

|

|

28'

4"

|

75,390

|

32'

2"

|

81,130

|

|

31'

|

85,820

|

34'

10"

|

91,595

|

|

33'

7"

|

96,285

|

37'

6"

|

102,060

|

|

36'

4"

|

106,715

|

40'

2"

|

112,525

|

|

39'

|

117,180

|

42'

11"

|

122,990

|

|

15

|

16'

8"

|

38,360

|

21'

7"

|

50,540

|

|

19'

4"

|

54,740

|

24'

4"

|

66,850

|

|

22'

|

71,155

|

26'

11"

|

83,160

|

|

24'

8"

|

87,570

|

29'

7"

|

99,470

|

|

27'

4"

|

103,985

|

32'

4"

|

115,815

|

|

30'

|

120,400

|

34'

11"

|

132,125

|

|

32'

8"

|

136,815

|

37'

7"

|

148,435

|

|

35'

5"

|

153,230

|

-

|

-

|

|

18

|

19'

|

56,000

|

-

|

-

|

|

21'

8"

|

79,485

|

-

|

-

|

|

24'

4"

|

103,005

|

-

|

-

|

|

27'

|

126,490

|

-

|

-

|

|

29'

8"

|

149,975

|

-

|

-

|

|

32'

5"

|

173,460

|

-

|

-

|

|

35'

|

196,980

|

-

|

-

|

|

37'

8"

|

220,500

|

-

|

-

|

In-Plant

Storage Bins In-Plant

Storage Bins

Standard

features:

- Vacuum

take off box with (4) 2” OD probes

- Butterfly

valve

- Braced

on (3) sides

- Sight

glass in side wall

- 45

degree hopper

- Slide

gate

- Hopper

and body constructed of 14 gauge steel

- Legs

are 3” x 3” x ¼” steel

- Roof

includes hinged access door, vent and hole for vacuum chamber

- Standard

discharge

- Exterior

finish - Customer’s choice of color

In-Plant

Storage Bin Specifications

|

Coast

Item

Number

|

Capacity

|

Hopper

Slope

(Degrees)

|

Height

(inches)

|

Width

(feet)

|

Approx.

Shipping Weight (Lbs.)

|

|

Cubic

ft.

|

Lbs.

|

|

CESB3045

|

30

|

1,000

|

45

|

52"

|

4'

x 4'

|

450

|

|

CESB6045

|

60

|

2,000

|

45

|

75"

|

4'

x 4'

|

575

|

|

CESB9045

|

90

|

3,000

|

45

|

76"

|

5'

x 5'

|

850

|

|

CESB14545

|

145

|

5,000

|

45

|

106"

|

5'

x 5'

|

1,050

|

|

CESB29045

|

290

|

10,000

|

45

|

135"

|

6'

x 6'

|

1,550

|

|

CESB3060

|

30

|

1,000

|

60

|

60"

|

4'

x 4'

|

475

|

|

CESB6060

|

60

|

2,000

|

60

|

83"

|

4'

x 4'

|

600

|

|

CESB9060

|

60

|

3,000

|

60

|

88"

|

5'

x 5'

|

900

|

|

CESB14560

|

145

|

5,000

|

60

|

118"

|

5'

x 5'

|

1,150

|

|

CESB29060

|

290

|

10,000

|

60

|

148"

|

6'

x 6'

|

1,650

|

Accessories:

Truck

Fill Level Sensor Panel

Features:

- NEMA

4

- Alarm

and silence button

- High

intensity extended life LED lights

|

Item

#

|

Product

Description

|

|

CETFP01

|

Single

Station

|

|

CETFP02

|

Two

Station

|

|

CETFP03

|

Three

Station

|

|

CETFP04

|

Four

Station

|

|

CETFP05

|

Five

Station

|

|

CETFP08

|

Eight

Station

|

|

Additional

Options:

|

|

Item

#

|

Product

Description

|

|

CETFPLL

|

Low

Level Light per Station

|

|

CETFPBVF

|

Bin

Vent Filter per Station

|

Truck

Fill Line:

Features:

|

Item

#

|

Product

Description

|

|

CETFA24

|

Truck

fill line with aluminum elbows for a 24 ft Silo

|

|

CETFA30

|

Truck

fill line with aluminum elbows for a 30 ft Silo

|

|

CETFA32

|

Truck

fill line with aluminum elbows for a 32 ft Silo

|

|

CETFA36

|

Truck

fill line with aluminum elbows for a 36 ft Silo

|

|

CETFA40

|

Truck

fill line with aluminum elbows for a 40 ft Silo

|

|

CETFA48

|

Truck

fill line with aluminum elbows for a 48 ft Silo

|

|

CETFA56

|

Truck

fill line with aluminum elbows for a 56 ft Silo

|

|

CETFA60

|

Truck

fill line with aluminum elbows for a 60 ft Silo

|

|

CETFS24

|

Truck

fill line with stainless steel elbows for a 24 ft Silo

|

|

CETFS30

|

Truck

fill line with stainless steel elbows for a 30 ft Silo

|

|

CETFS32

|

Truck

fill line with stainless steel elbows for a 32 ft Silo

|

|

CETFS36

|

Truck

fill line with stainless steel elbows for a 36 ft Silo

|

|

CETFS40

|

Truck

fill line with stainless steel elbows for a 40 ft Silo

|

|

CETFS48

|

Truck

fill line with stainless steel elbows for a 48 ft Silo

|

|

CETFS56

|

Truck

fill line with stainless steel elbows for a 56 ft Silo

|

|

CETFS60

|

Truck

fill line with stainless steel elbows for a 60 ft Silo

|

Aluminum

Slide Gate

|

Item

#

|

Product

Description

|

|

CEASG12

|

12"

Aluminum slide gate with hand wheel

|

Vacuum

Take Off Box

Features:

- Available

in Aluminum or Stainless Steel

- Aluminum

probes available in sizes 1 ½" - 4" OD

|

Item

#

|

Product

Description

|

|

CEAVB1

|

Aluminum

vacuum take off box with one hole

|

|

CEAVB2

|

Aluminum

vacuum take off box with two holes

|

|

CEAVB3

|

Aluminum

vacuum take off box with three holes

|

|

CEAVB4

|

Aluminum

vacuum take off box with four holes

|

|

CEAVB6

|

Aluminum

vacuum take off box with six holes

|

|

CEAP15

|

Aluminum

1 ½" OD probe

|

|

CEAP20

|

Aluminum

2" OD probe

|

|

CEAP25

|

Aluminum

2 ½" OD probe

|

|

CEAP30

|

Aluminum

3" OD probe

|

|

CEAP40

|

Aluminum

4" OD probe

|

|

Options:

|

|

Item

#

|

Product

Description

|

|

CEVBCP

|

Vacuum

take off box cover plate

|

|

CEVBC

|

Cover

|

|

CEMP15

|

1

½" OD material plug

|

|

CEMP20

|

2"

OD material plug

|

|

CEMP25

|

2

½" OD material plug

|

|

CEMP30

|

3"

OD material plug

|

|

CEMP40

|

4"

OD material plug

|

|

CEBCOD

|

Bolted

on clean out door

|

|

|

|